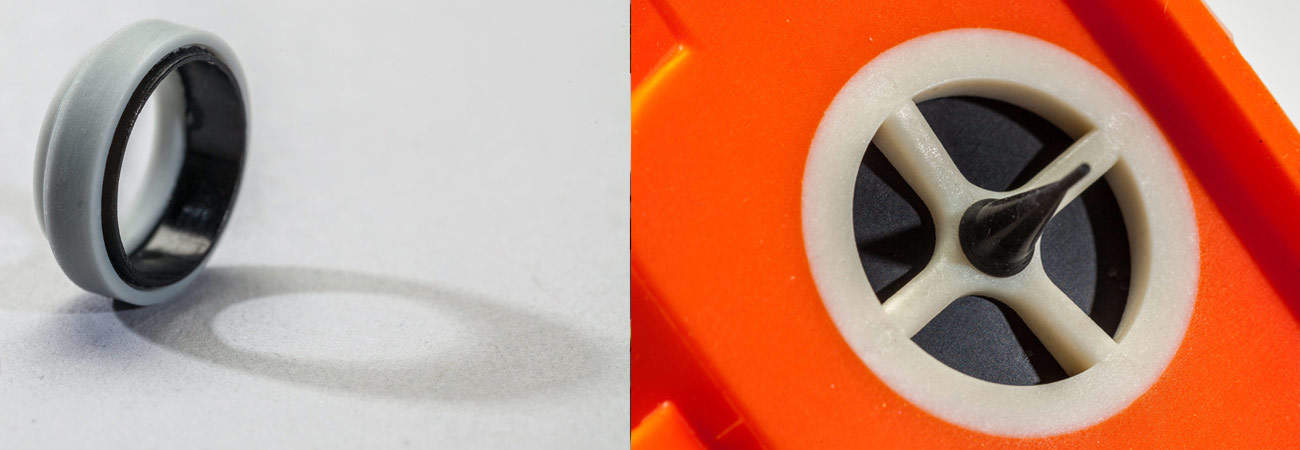

RD Rubber Technology provides its customers with some of the most advanced solutions for silicone to plastic bonding. RD Rubber Technology uses both chemical and mechanical bonding techniques to mold rubber to a variety of substrates including high-temperature plastics, steel, stainless steel, brass, and aluminum.

Chemical bonding – chemical bonding agents assist rubber in bonding to many plastic materials. This process is used where over-molding is necessary. Our chemical bonding meets ASTM D429.

Silicone to Plastic bonding provides the following benefits:

- Ensures that seals are tight.

- Reduces the number of components in an assembly.

- Specialized design possibilities.

- Keeps seals in the proper place with proper alignment – avoids human error.

- Perfect for seals or rollers and parts that encounter force and movement.

- Value-added grinding and finishing.