A type of synthetic rubber, ethylene propylene diene monomer (EPDM) possesses a molecular structure consisting of one bond and a chemically saturated foundation. Its makeup gives the material a high resistance to a multitude of substances and environmental conditions. For that reason, EPDM is an ideal material choice for sealing products like gaskets and O-rings.

At RD Rubber Technology Corp., we specialize in the manufacture of custom-molded parts from high-performance rubbers like EPDM. Learn about the properties of these components, their applications, and their benefits for various operations.

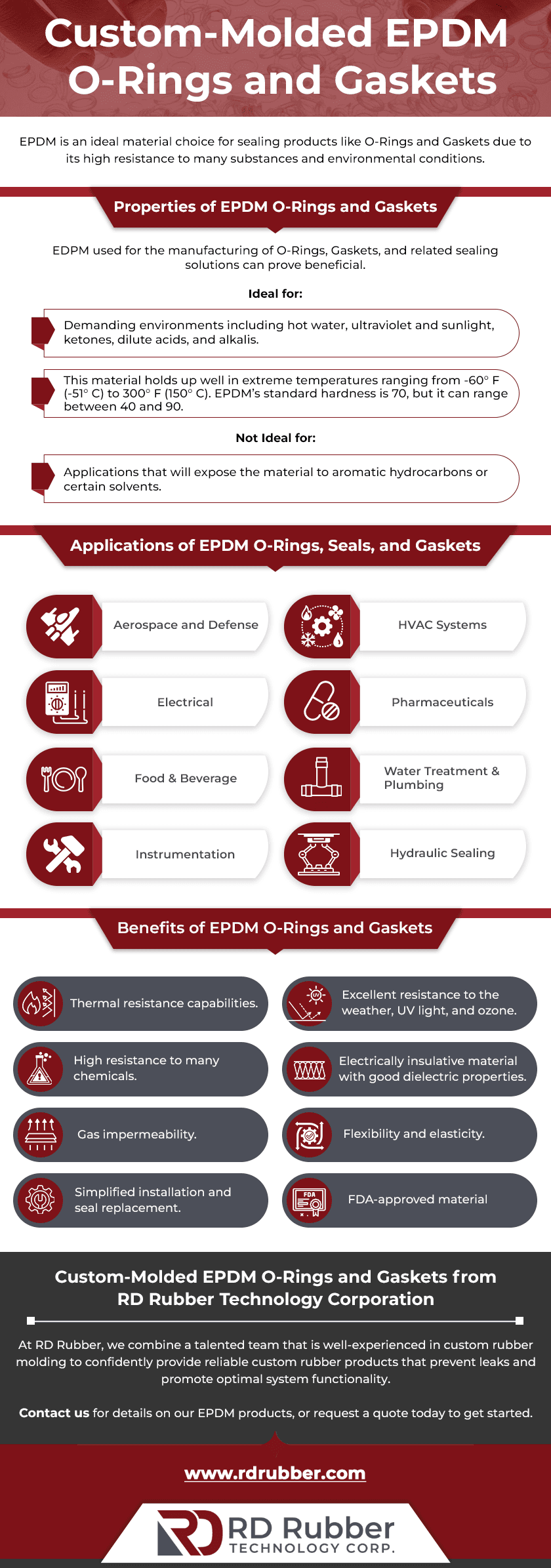

Properties of EPDM Gaskets & O-Rings

Using EPDM in the manufacture of gaskets, O-rings, and related sealing solutions offers critical in demanding environments including hot water, steam, cold weather, ultraviolet and sunlight, ketones, dilute acids, and alkalis. EPDM gaskets and O-rings are not, however, ideal for applications that will expose them to aromatic hydrocarbons or certain solvents.

This material holds up well in extreme temperatures ranging from -60° F (-51° C) to 300° F (150° C). EPDM’s standard hardness is 70, but it can range between 40 and 90. RD Rubber is equipped to customize EPDM products based on your application’s unique requirements for durometer, color, industry standard compliance, and customized testing.

Applications of EPDM O-Rings, Seals, & Gaskets

EPDM seals, O-rings, and gaskets have applications throughout numerous demanding industries.

Aerospace & Defense

EPDM gaskets and O-rings are utilized in aerospace and military systems to reliably maintain sealing capabilities against corrosive chemicals, high- and low-pressure applications, extreme temperatures, and conditions in static and dynamic applications.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems often rely on EPDM gaskets and O-rings because of their beneficial properties. Their material provides superior resistance to light and the elements, making them ideal for exterior HVAC equipment. EPDM components also allow for better sealing, reducing the likelihood of refrigerant and air leaks.

Electrical

External cable connectors, electrical enclosures, and other outdoor electrical components similarly depend on EPDM gaskets and O-rings for their resistance to outdoor environments. The electrically insulative nature of EPDM also makes it great for electrical applications to boost a system’s dependability and safety.

Pharmaceuticals

Pharmaceutical applications for EPDM O-rings and gaskets include sealing for valves, pumps, connectors, and other equipment. Their main benefits for this industry include the ability to endure hot water, steam, and chemicals involved in manufacturing pharmaceuticals.

Food & Beverage

EPDM’s resistance properties and reliability make its O-rings and gaskets suitable for many food and beverage applications. Specifically, this industry often uses EPDM sealing solutions to meet strict requirements surrounding durability and hygiene for safe, consumable products.

Water Treatment & Plumbing

Plumbing systems, water distribution systems, and water treatment facilities can all use EPDM O-rings and gaskets because of their resistance to substances inherent to these environments, such as chemicals, steam, and water.

Instrumentation

Certain instrumentation applications use EPDM components to seal tubing, piping, and other connections and keep a system working optimally. EPDM is ideal for this industry because of its resistance to water, steam, heat, UV light, ozone, alkalis, and milder oxygenated and acidic solvents.

Hydraulic Sealing

Due to the same resistance factors that are beneficial to the instrumentation sector, EPDM O-rings and gaskets provide maximum protection against degradation when faced with hydraulic fluids in tubes and pipes within hydraulic systems.

Benefits of EPDM Gaskets & O-Rings

The following are some of the specific advantages of EPDM sealing products:

- Thermal resistance capabilities. EPDM offers good thermal resistance, maintaining its physical integrity under hot, cold, and fluctuating temperatures.

- Excellent resistance to the weather, UV light, and ozone. Using EPDM for gaskets and O-rings protects seals from degradation when faced with weathering, sunlight, and ozone, even under extended exposure.

- High resistance to many chemicals. EPDM resists many alkalis, acids, and polar solvents, which is why it’s an ideal choice for harsh chemical environments.

- Electrically insulative material with good dielectric properties. This synthetic rubber offers good dielectric qualities that make it suitable for applications as electrical insulation, preventing electrical conductivity.

- Gas impermeability. EPDM keeps gas from escaping its structure, providing a good gasket and O-ring material option for applications requiring low or no gas permeability.

- Flexibility and elasticity. The material’s flexibility and elasticity allow for a tight seal regardless of changes in temperature or pressure and whether mating surfaces are smooth, rough, or irregular.

- Simplified installation and seal replacement. EPDM’s flexibility and elasticity have the added benefit of making its gaskets and O-rings fairly simple to install and change out. It’s also compatible with a range of flange materials.

- FDA-approved material. The Food and Drug Administration (FDA) has approved EPDM O-rings and gaskets for food and beverage applications.

Custom-Molded EPDM Gaskets & O-Rings From RD Rubber Technology Corporation

At RD Rubber, we combine a talented team that is well experienced in custom rubber molding to confidently provide reliable custom rubber products that prevent leaks and promote optimal system functionality. We engineer sealing solutions for clients in industries ranging from aerospace and defense to healthcare and pharmaceuticals, utilizing high-performance thermoset elastomer materials like EPDM, butyl, organic and synthetic rubber, nitrile, neoprene, Viton®, and much more.

Contact us for details on our EPDM products, or request a quote today to get started.