The copolymer butyl has an ASTM designation of IIR (isobutylene isoprene rubber). This synthetic rubber strikes an ideal balance between flexibility and durability, making it an effective choice

for water- and airtight sealing applications. It ranges in hardness between 30 and 90, Shore A, and has a shelf life of 15 years. Where it truly impresses, however, is with its range of resistance capabilities.

RD Rubber Technology Corp. is a trusted supplier of custom-engineered rubber products. Among our line of sealing solutions are our high-performance butyl O-rings, seals, and gaskets. Learn how partnering with RD Rubber for your sealing needs can help support your operations, as well as the many benefits and applications of our butyl products.

Buy Custom-Engineered Butyl O-Rings, Seals, & Gaskets From RD Rubber

At RD Rubber, we utilize state-of-the-art manufacturing equipment and technology to produce rubber products in volumes ranging from single prototypes to large production runs to best meet our customers’ individual needs. To that end, we also provide flexible, personalized service to ensure superior customer satisfaction. Our team adheres to strict quality standards and we maintain ISO and AS certifications to make sure you receive sealing components that can withstand high pressures, extreme and fluctuating temperatures, and caustic substances.

In addition to our manufacturing capabilities, RD Rubber offers in-house prototyping and engineering services. The engineering process starts with a comprehensive review of your sealing needs. Our team will then recommend the ideal material, molding method, and more to optimize your product, operations, and project budget.

Butyl’s Resistance Capabilities

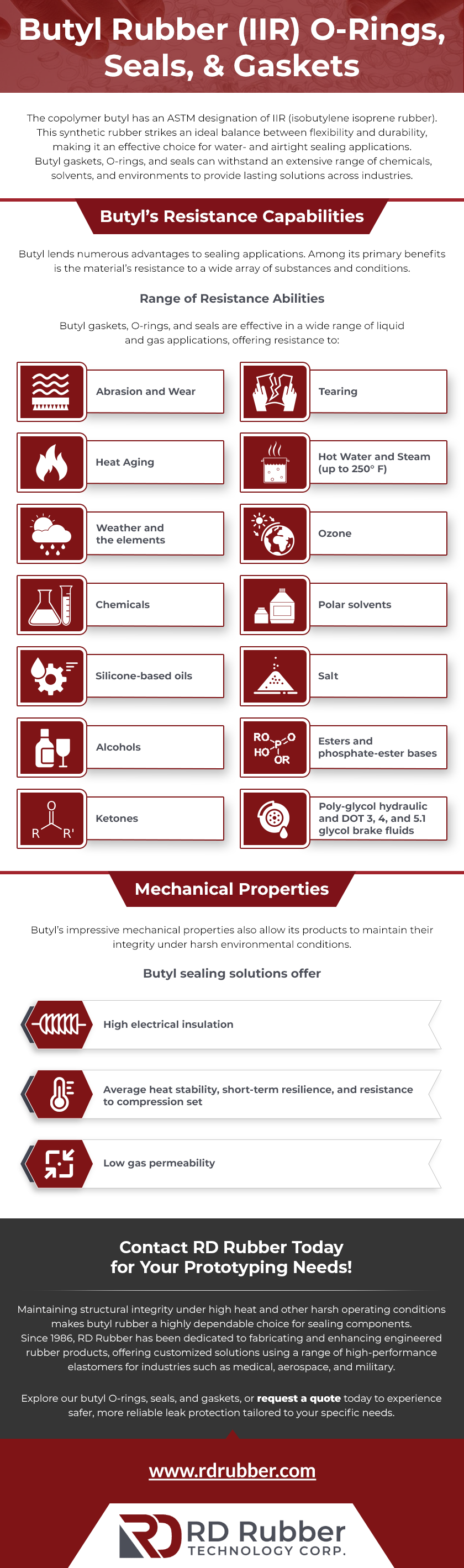

Butyl lends numerous advantages to sealing applications. Among its primary benefits is the material’s resistance to a wide array of substances and conditions.

Range of Resistance Abilities

Butyl gaskets, O-rings, and seals are effective in a wide range of liquid and gas applications, offering resistance to:

- Abrasion and wear

- Tearing

- Heat aging

- Hot water and steam (up to 250° F)

- Weather and the elements

- Ozone

- Chemicals

- Polar solvents

- Silicone-based oils

- Salt

- Alcohols

- Esters and phosphate-ester bases

- Ketones

- Poly-glycol hydraulic and DOT 3, 4, and 5.1 glycol brake fluids

Resistance Constraints

Despite its long list of resistance capabilities, please note that butyl is not suitable for those applications that would expose the material to:

- Standard fuel varieties

- Chlorinated hydrocarbon- and petroleum-based solvents

- Coal tars

- Mineral oils

Mechanical Properties

In addition to butyl’s ability to resist a myriad of substances, its impressive mechanical properties also allow its products to maintain their integrity under harsh environmental conditions. Butyl sealing solutions offer:

- High electrical insulation

- Average heat stability, short-term resilience, and resistance to compression set

- Low gas permeability

Butyl O-Rings, Seals, & Gaskets: Applications in the Defense Industry

While butyl’s unique properties give it versatile compatibility with applications in numerous industries, butyl is especially useful to the aerospace and defense sector. The military depends on precise, durable components and specialized, high-performance materials to handle mission-critical applications. RD Rubber proudly supplies our military and aerospace clients with high-quality butyl seal components, all of which come with a certificate confirming compliance with ITAR and AS 9100:2016 standards.

Custom-Engineered Butyl O-Rings, Seals, & Gaskets From RD Rubber

By maintaining structural integrity under high heat and other harsh operating conditions, butyl rubber is a highly dependable choice for sealing components. Butyl gaskets, O-rings, and seals can withstand an extensive range of chemicals, solvents, and environments to provide lasting solutions across industries.

Since 1986, RD Rubber has been committed to finding new ways to fabricate and refine our engineered rubber products, providing clients in markets from medical and pharmaceutical to aerospace and military with safer, more reliable leak protection. We utilize butyl, chlorobutyl, EPDM, silicone, neoprene, nitrile, and a wide selection of other high-performance thermoset elastomers to develop customized solutions tailored to your needs. Contact us to learn more about our butyl O-rings, seals, and gaskets, or request a quote today.