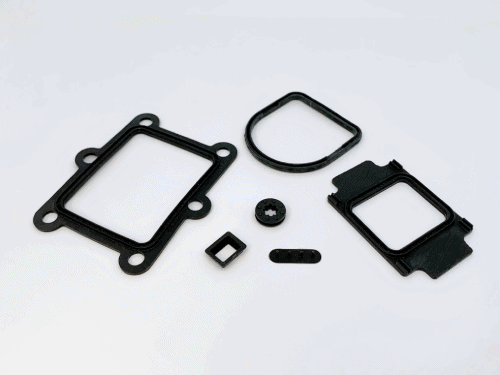

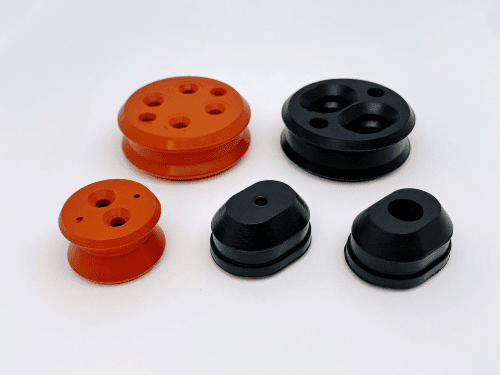

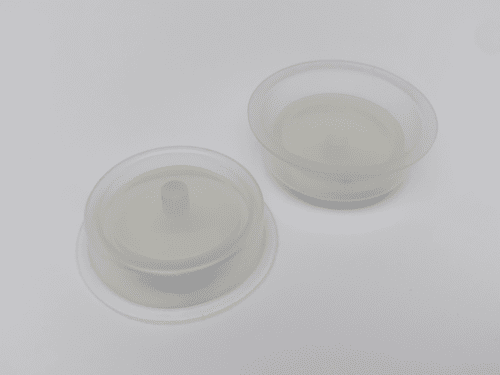

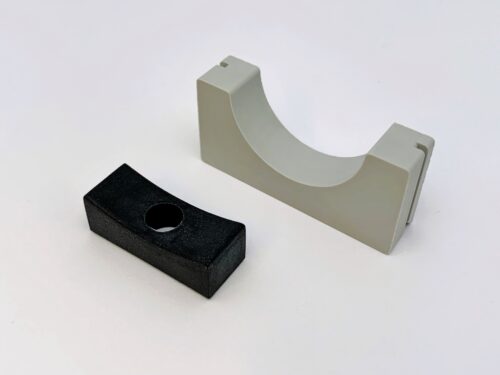

RD Rubber Technology Corporation specializes in the manufacture of custom precision molded rubber parts for many applications. From the development and testing of prototypes to the full-scale production of custom rubber parts, our experienced team has an intense commitment to every customer to ensure quality products and services our customers can trust. We provide OEM and aftermarket custom rubber parts across a wide range of industries while meeting the highest quality standards.

RD Rubber’s Product Applications

RD Rubber Technology Corporation specializes in custom precision molded rubber applications for the defense, military, aerospace, government, nuclear, food processing, life sciences, medical instruments, pharmaceutical, biopharmaceutical, pump, and semiconductor industries. Some of the most prevalent product applications include: