Seals and gaskets provide sealing to prevent gases and liquids from entering or exiting a sealed component. They are made from various materials to suit their intended applications and conditions and form a tight seal through the compression of two mating parts. Nitrile gasket materials are preferred in various industries due to their exceptional resistance to chemicals and temperature and their ability to conform to numerous shapes.

RD Rubber Technology Corp has produced custom rubber products since 1986. We offer various nitrile seals and gaskets to suit any application. Understanding the properties, types of seals, and their applications will help you select the ideal solution for your application.

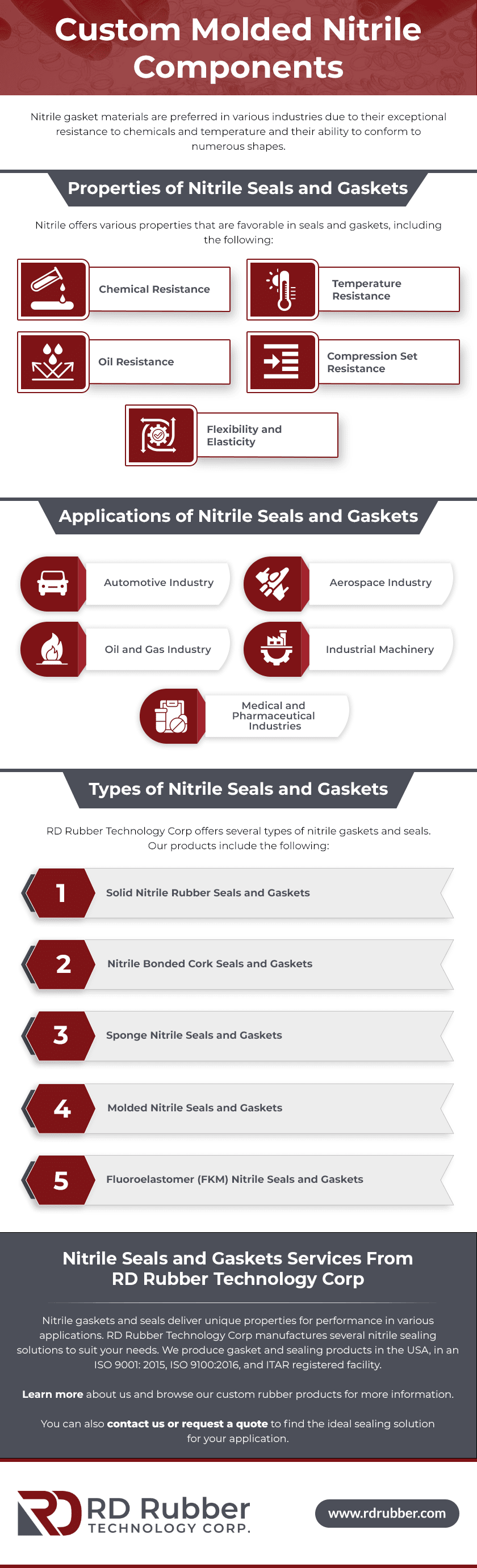

Properties of Nitrile Seals and Gaskets

Nitrile offers various properties that are favorable in seals and gaskets, including the following:

- Chemical Resistance: Components molded from nitrile offer exceptional resistance to solvents, fuels, oils, and other chemicals. Its chemical resistance makes nitrile ideal for applications where chemical exposure is likely.

- Temperature Resistance: Nitrile can withstand operating temperatures from -40°C to +120°C (-40°F to +250°F), allowing nitrile components to maintain their characteristics and performance in extreme conditions.

- Oil Resistance: Nitrile offers high resistance to oils, making it ideal for sealing applications prone to oil exposure, such as the automotive and industrial sectors.

- Compression Set Resistance: Molded nitrile seals offer good compression set resistance, allowing them to recover from compression, resisting permanent deformation, and maintaining their original shape. Compression set resistance ensures that nitrile components maintain sealing performance long-term.

- Flexibility and Elasticity: Nitrile offers excellent elasticity and flexibility. Components can maintain a reliable seal while conforming to irregular shapes in dynamic applications.

Applications of Nitrile Seals and Gaskets

Nitrile gaskets and seals are suitable for various applications. Some of the industries that rely on nitrile sealing products include the following:

- Automotive Industry: The automotive industry relies on nitrile gasket materials and seals due to their resistance to automotive fluid, fuel, and oil exposure. Nitrile seals are ideal for hydraulic, fuel, engine, and transmission systems.

- Aerospace Industry: Nitrile gaskets and seals offer resistance to hydraulic fluids, oils, and aviation fuels the aerospace industry requires. Aircraft fuel, hydraulic, landing gear, and engine systems depend on nitrile seals.

- Oil and Gas Industry: Various applications in the oil and gas sector rely on nitrile gaskets and seals, including pumps, valves, and pipelines. Nitrile gasket materials offer suitable resistance to hydraulic fluids, gas, fuel, and oils and performance in demanding conditions.

- Industrial Machinery: Nitrile gaskets and seals are an ideal solution for process equipment, valves, compressors, and pump sealing. They effectively seal against industrial chemicals, solvents, greases, and oils.

- Medical and Pharmaceutical Industries: Medical and pharmaceutical applications depend on nitrile gaskets and seals for their resistance to chemicals used in sanitization. Applications, including healthcare facilities, pharmaceutical manufacturing, laboratory equipment, and medical devices, use nitrile sealing materials.

Types of Nitrile Seals and Gaskets

RD Rubber Technology Corp offers several types of nitrile gaskets and seals. Our products include the following:

- Solid Nitrile Rubber Seals and Gaskets: A solid nitrile rubber sealing component cut from a single piece of nitrile. Solid nitrile rubber seals offer exceptional resistance to chemicals, fuels, and oils for various applications.

- Nitrile Bonded Cork Seals and Gaskets: A seal made from nitrile rubber gasket material with a cork core that provides resilience and compressibility in addition to the inherent chemical resistance of nitrile. Nitrile-bonded cork seals are ideal for automotive sealing applications.

- Sponge Nitrile Seals and Gaskets: A seal made from a sponge-like nitrile formulation. Sponge nitrile gaskets offer improved compressibility and cushioning to produce a tight seal.

- Molded Nitrile Seals and Gaskets: A seal molded in a specific shape from nitrile material in a custom mold. Molded nitrile seals offer good sealing for applications that require a custom solution.

- Fluoroelastomer (FKM) Nitrile Seals and Gaskets: A seal produced from a blend of nitrile rubber and FKM, offering enhanced chemical and high-temperature resistance. FKM nitrile seals are ideal for applications in demanding conditions.

Nitrile Seals and Gaskets Services From RD Rubber Technology Corp

Nitrile gaskets and seals deliver unique properties for performance in various applications. RD Rubber Technology Corp manufactures several nitrile sealing solutions to suit your needs. We produce gasket and sealing products in the USA, in an ISO 9001: 2015, ISO 9100:2016, and ITAR registered facility. Our custom rubber molding capabilities include liquid injection molding, rubber compression molding, and rubber transfer molding to create an ideal seal for any application. We have delivered innovative sealing solutions for several critical industries, including the military and aerospace sectors.

Learn more about us and browse our custom rubber products for more information. You can also contact us or request a quote to find the ideal sealing solution for your application.