The early 20th century brought unprecedented demand for rubber across a variety of industries and applications. Scientists developed the first synthetic rubbers — isoprene and neoprene — soon followed by Buna rubber. These and more recent innovations in synthetic rubber have expanded to offer solutions that outperform natural rubber.

The early 20th century brought unprecedented demand for rubber across a variety of industries and applications. Scientists developed the first synthetic rubbers — isoprene and neoprene — soon followed by Buna rubber. These and more recent innovations in synthetic rubber have expanded to offer solutions that outperform natural rubber.What Is Synthetic Rubber?

Synthetic rubber is a polymer material, meaning it’s made of large molecules formed of simpler, identical molecules (monomers). Polymers can be natural (such as silk or natural rubber) or synthetic (such as plastics or synthetic rubbers). Industrial processes commonly used to create synthetic rubber include solution and emulsion polymerization which add rubber monomers to a solvent-based or water-based mixture to convert the monomers into polymers.

Comparing Natural & Synthetic Rubbers

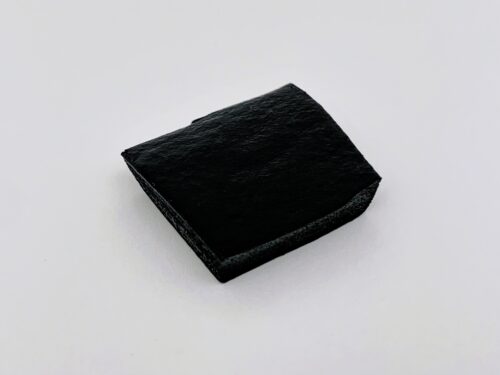

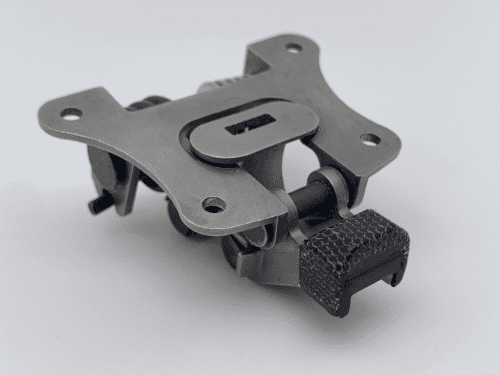

Natural rubber is versatile and renewable material for traditional applications such as tires and shoe soles. While natural rubber generally performs well in most environments and uses, its use is limited to high-temperature applications, with an operating temperature of around 180°C/356 °F. Synthetic rubbers can be formulated specifically to address these and other performance requirements by using different combinations of monomers and selected additives. Many types of synthetic rubber are used for critical applications including gaskets, seals, O-rings, grommets, diaphragms, and poppets.