Rubber to Metal Bonding

Rubber to metal bonding forms a permanent, durable connection between rubber and metal components. The combination of the two materials offers superior resistance to vibration damage and mechanical stress, allowing components to withstand wider environmental conditions.

RD Rubber is committed to creating high-quality products through in-house manufacturing and engineering capabilities. Our company is ISO 9001:2015 certified, AS 9100:2016 certified, ITAR registered, NIST 800-171 compliant, and registered with the Department of Defense to serve military applications.

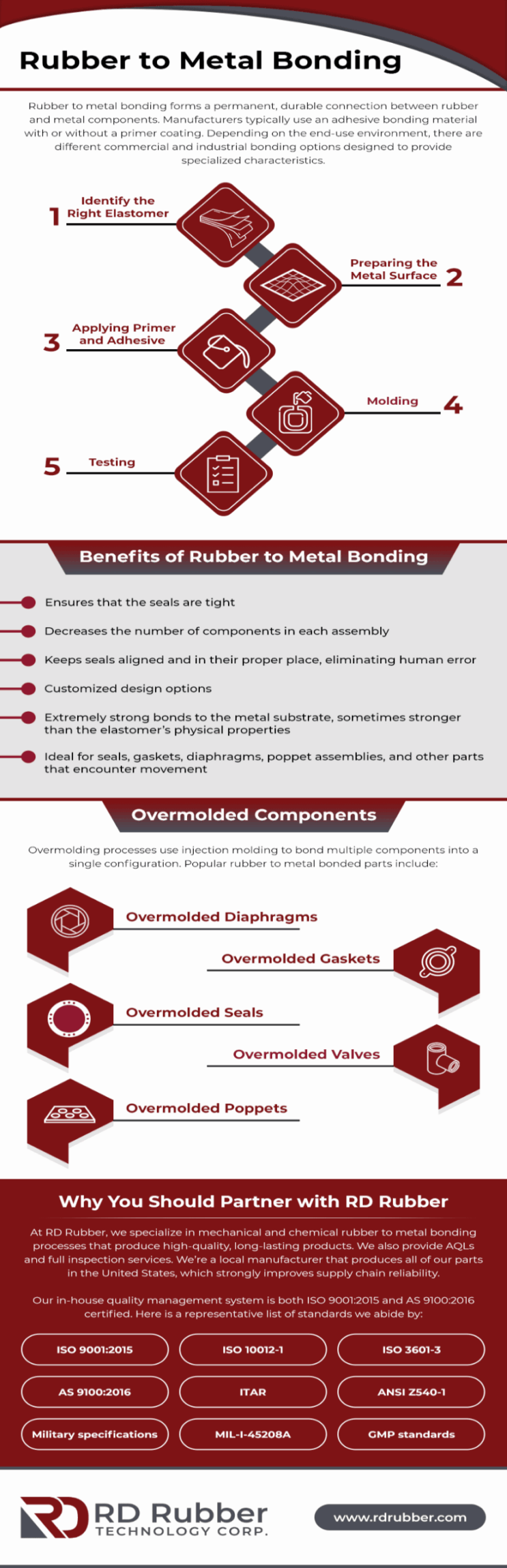

Rubber to Metal Bonding Process

RD Rubber uses a well-designed, time-tested process for rubber to metal bonding. We follow these five steps to ensure consistent performance:

1. Identify the Right Elastomer

Natural and synthetic rubbers can both be bonded to metal substrates, but they require different preparation methods and are paired with different fillers to give the material new characteristics. At this stage, the rubber does not exhibit its desired properties until it is cured in the molding process.

2. Preparing the Metal Surface

After deciding on the proper elastomer material, manufacturers prepare the surface of the metal substrate. First, the surface needs to be thoroughly cleaned with a degreasing solvent and stored away from moisture. If the parts need to be handled manually, technicians should wear gloves or use a cloth so the parts are maintained in pristine condition.

3. Applying Primer and Adhesive

Vulcanization bonding is the most common choice for creating a strong metal to rubber bond. This involves applying a specialty primer and cement bonding agent to a cleaned and prepped metal surface. We then place unvulcanized rubber onto the adhesive-covered metal surface, applying heat and pressure to chemically alter the rubber and create a strong bond.

4. Molding

After the adhesive application, the molding stage should take place as soon as possible.

A common molding technique is rubber compression molding, which is a closed mold process that produces low to medium volumes of rubber to metal bonded components. Compression molding involves positioning an uncured rubber preform or profile into a heated mold, which applies high clamping pressure to fill the cavities with the rubber material. The rubber takes the shape of the mold and is cured into a finished molded component. Once the part finishes curing, technicians cut off excess material and set aside the bonded parts.

5. Testing

After molding, the parts are tested to ensure the bond, tensile strength, and other properties meet customer specifications. Manufacturers also test the components according to the standards established in ASTM D429. Common performance modes to test include 1) the strength of the rubber and adhesive bond, 2) the strength between the primer and adhesive layer, and 3) the strength between the adhesive and the metal.

There are many variables throughout this five-step process that can impact the final results. For example, using the right glues and adhesives can ensure durable bonds in the intended application.

Considerations for Your Intended Application of Your Rubber to Metal Bonded Part

Our team at RD Rubber has experience working to meet a range of application-specific requirements. Some of the most common projects we provide rubber to metal bonding services for include:

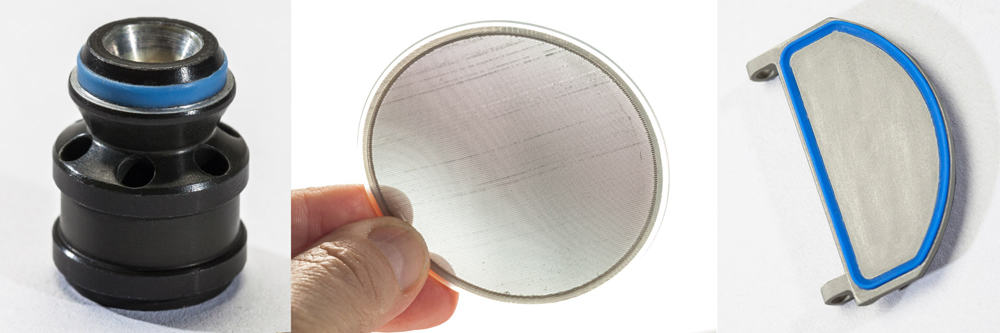

- Overmolded components. Popular overmolded components include overmolded diaphragms, gaskets, poppers, seals, and valves.

- Industrial components. We produce rubber to metal bonded parts such as covers and cases, plungers and vacuum cups, connectors, flappers, shells, and housings. We can also provide latches, nozzles, plungers, switches, and other parts.

- Moving parts. Rubber to metal bonding is ideal for rollers, seals, and other parts that encounter movement or force as part of regular use.

Each of these different products will need a bond that can withstand different environmental conditions, stresses, and sources of damage over time. Consider the following application and environmental conditions to account for sources of damage or degradation:

- Chemical exposure. Consider what chemicals it might come into contact with, whether it’s moisture or stronger chemicals like acids, oils, fuels, alkalis, and solvents.

- Cost. Consider your budget for non-recurring engineering tooling and parts manufacturing as part of the overall project costs.

- Environmental hazards. Some applications, especially exterior applications, can involve exposure to ozone, UV radiation, and weathering.

- Loads. Consider whether components will need to withstand dynamic forces through vibration isolation or if they will need to handle static loads.

- Mechanical stress. Will the piece be under continuous or dynamic stress? This can include abrasion, compression, impact, shear stress, tension, and vibration forces.

- Operating temperature range. Will the products be subjected to very high temperatures (i.e., engine mounts), or will they need to withstand extreme cold? Some components, like outdoor seals, may need to withstand high and low temperatures.

RD Rubber’s specialists can help you consider these and other factors to determine the right bonding process.

Common Materials Used in Rubber to Metal Bonding

Modern bonding chemicals create a very strong bond, sometimes even stronger than the characteristics of the polymer material itself. At RD Rubber, we can work with a wide range of thermoset elastomers and rubber material options, including the following high-performance synthetic rubbers:

- Butyl

- Ethylene-Propylene (EPDM)

- Fluoroelastomer (FKM/Viton)

- Fluorosilicone

- Nitrile (NBR)

- Silicone (VMQ)

Our process can create tight seals that stay aligned and properly positioned. Once bonded, the rubber can effectively shield metal components, ensuring a longer-lasting seal that resists shock and minimizes noise through vibration isolation and damping. This layer can also protect the metal from corrosive chemicals, abrasion, and environmental hazards, leading to a longer product lifespan.

RD Rubber's Quality Assurance Standards

At RD Rubber, we’re committed to providing high-quality rubber products. Our dimensional inspections are capable of precision measurements ranging from 0.0003″ to 14.000″. We adhere to the following standards to offer our clients unmatched results across our services:

- ISO 9001:2015, ISO 10012-1, ISO 3601-3, AS 9100:2016, and ANSI Z540-1 certified

- Compliant with Mil-Spec standards, including MIL-I-45208A

- Compliant with GMP standards

- ITAR and Department of Defense registered

- NIST 800-171 compliant

Partner With RD Rubber Today for Your Rubber to Metal Bonding Project

RD Rubber serves demanding industries with our rubber to metal bonding processes. As part of our local manufacturing services, we provide in-house AQLs and full inspection services so that you can have more confidence in your supply chain.

Contact RD Rubber to learn more about our engineered rubber solutions or request a quote to start your order.

Rubber to Metal Bonding

Rubber to metal bonding forms a permanent, durable connection between rubber and metal components. Manufacturers typically use an adhesive bonding material with or without a primer coating.

Contact UsOur value propositions