Rubber transfer molding is an effective form of rubber molding that produces high-quality rubber parts. At RD Rubber Technology Corp., we specialize in a variety of rubber molding techniques to meet the needs of customers across different industries. Learn more about how rubber transfer molding works, its benefits, and common applications.

How Rubber Transfer Molding Works

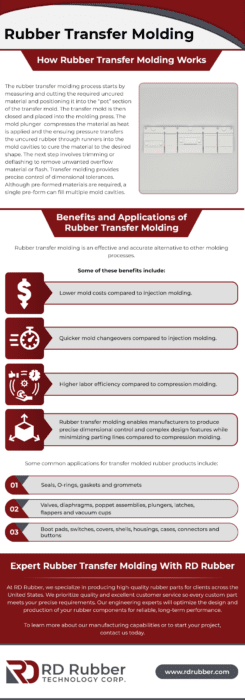

The rubber transfer molding process starts by measuring and cutting the required uncured material and positioning it into the “pot” section of the transfer mold. The transfer mold is then closed and placed into the molding press. The mold plunger compresses the material as heat is applied and the ensuing pressure transfers the uncured rubber through runners into the mold cavities to cure the material to the desired shape. The next step involves trimming or deflashing to remove unwanted overflow material or flash. Transfer molding provides precise control of dimensional tolerances. Although pre-formed materials are required, a single pre-form can fill multiple mold cavities.

Benefits and Applications of Rubber Transfer Molding

Rubber transfer molding is an effective and accurate alternative to other molding processes. Some of these benefits include:

- Lower mold costs compared to injection molding.

- Quicker mold changeovers compared to injection molding.

- Higher labor efficiency compared to compression molding.

- Rubber transfer molding enables manufacturers to produce precise dimensional control and complex manufacturing features while minimizing parting lines compared to compression molding.

Some common applications for transfer molded rubber products include:

- Seals, O-rings, gaskets and grommets

- Valves, diaphragms, poppet assemblies, plungers, latches, flappers and vacuum cups

- Boot pads, switches, covers, shells, housings, cases, connectors and buttons

Expert Rubber Transfer Molding With RD Rubber

At RD Rubber, we specialize in producing high-quality rubber parts for clients across the United States. We prioritize quality and excellent customer service so every custom part meets your precise requirements. Our engineering experts will optimize the manufacturing process and production of your rubber components for reliable, long-term performance.

We maintain quality control throughout the quoting, tooling, manufacturing, and inspecting stages. In addition to being ISO 9001:2015 and AS 9100:2016 certified, RD Rubber complies with the following standards:

- ANSI Z540-1

- ISO 10012-1 and ISO 3601-3

- ITAR registration

- GMP standards

- MIL-I-45208A

To learn more about our manufacturing capabilities or to start your project, contact us today.