Rubber compression molding is an effective manufacturing process used to form components out of rubber and thermoset elastomers. This processing method uses material preforms to mold rubber into the desired shape and is suitable for low to medium production volumes. Rubber compression molding is versatile and is used to create a range of simple or complex components, including seals, O-rings, gaskets, grommets, valves, diaphragms, poppet assemblies, plungers, latches, flappers, vacuum cups, boot pads, switches, covers, shells, housings, cases, connectors, and buttons and other critical to function products.

At RD Rubber Technology Corporation, rubber compression molding is one of our core capabilities. We serve industries with stringent performance demands, including aerospace, medical, defense, and food and dairy processing, among others.

We are ISO 9001:2015 and AS 9100:2016 certified and ITAR registered, Department of Defense (DoD) registered, and NIST 800-171 compliant. These certifications mean you can trust our commitment to meeting quality and security standards. Learn more about our rubber compression molding services.

Rubber Compression Molding Process

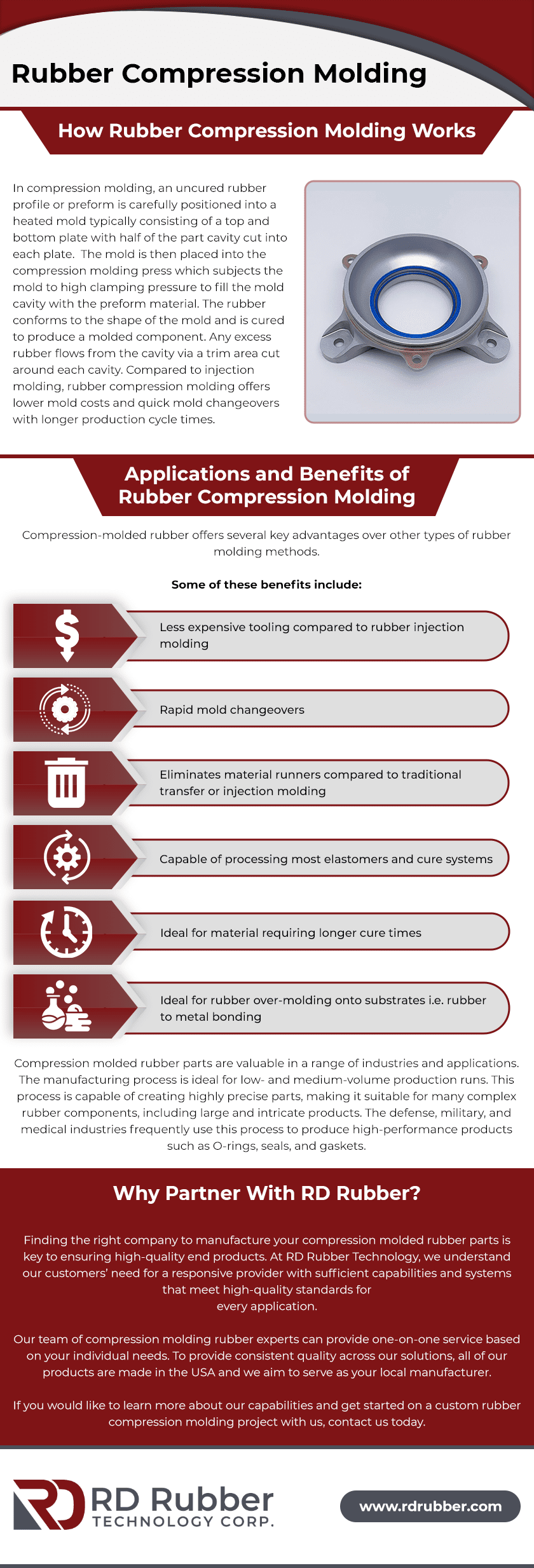

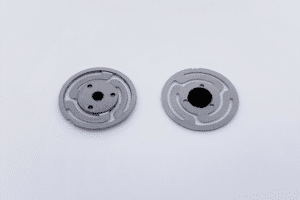

In rubber compression molding, an uncured rubber profile, or preform, is carefully positioned into a heated mold typically consisting of a top and bottom plate with half of the part cavity cut into each plate. The mold is then placed into the compression molding press which subjects the mold to high clamping pressure to fill the mold cavity with the preform material. The rubber conforms to the shape of the mold and is cured to produce a molded component. Any excess rubber flows from the cavity via a trim area cut around each cavity. Compared to injection molding, rubber compression molding offers lower mold costs and quick mold changeovers with longer material cure and production cycle times.

Materials Used in Rubber Compression Molding

RD Rubber works with an extensive list of elastomeric materials to meet performance, regulatory, and environmental requirements. Our in-house engineering team can help identify the best material for your application.

These are the most commonly used materials in rubber compression molding:

- Nitrile Rubber (NBR / Buna-N). This Offers excellent resistance to oil, fuel, and hydrocarbons.

- Buna-S (SBR). Durable and abrasion-resistant, SBR is suitable for industrial wear applications.

- Ethylene Propylene Diene Monomer (EPDM). This material Can withstand ozone, UV exposure, and high temperatures.

- Fluorocarbon Rubber (FKM / Viton®). This is Chemically resistant and heat-tolerant.

- Silicone (LIM, HCR). Biocompatible and stable at high temperatures, silicone is ideal for medical and food-grade applications.

Other materials that can be used for rubber compression molding include:

- Neoprene

- Butyl

- Chlorobutyl

- Fluorosilicone

Applications & Components Produced With Rubber Compression Molding

Rubber compression molding is trusted in many high-spec industries where precision and durability are essential for critical to function applications. RD Rubber produces components used in, but not limited to:

- Aerospace and defense systems

- Medical devices and diagnostics

- Food and dairy processing equipment

- Industrial machinery and control systems

Our expertise in rubber compression molding ensures each part meets exact tolerances and functional specifications, even in the most challenging environments. We manufacture a wide range of custom-molded rubber products, including:

- Rubber O-rings. These Essential sealing solutions are used in hydraulic, pneumatic, and vacuum systems.

- Rubber Gaskets. These Form tight seals between surfaces, preventing leaks or contamination.

- Rubber Seals. These seals are Custom-designed to isolate fluids, gases, and environmental elements.

- Rubber Diaphragms. Flexible membranes that separate or regulate pressure across chambers.

- Rubber Grommets. These Protect cables and wires from friction, cuts, and vibration as they pass through openings in panels or components.

- Rubber Latches. Ideal for applications where corrosion resistance and flexibility are needed.

- Rubber Valves. Used to regulate pressure and flow in fluid and gas control systems.

- Rubber Bushings. These Provide vibration damping and mechanical isolation in high-impact environments.

- Others. Poppets, covers, connectors, custom-shaped elastomer parts for specialized applications.

Learn more about all of our rubber molding capabilities, processes, and quality-engineered rubber products.

Benefits of Rubber Compression Molding

Compression-molded rubber offers several key advantages over other types of rubber molding methods. Some of these benefits include:

- Rapid mold changeovers

- Eliminates material runners compared to traditional transfer or injection molding

- Less expensive tooling compared to rubber injection molding

- Capable of processing most elastomers and cure systems

- Ideal for material requiring longer cure times

- Ideal for rubber over-molding onto substrates i.e. rubber to metal bonding

Compression molded rubber parts are valuable in a range of industries and applications. The manufacturing process is ideal for low- and medium-volume production runs and is capable of creating highly precise parts, making it suitable for many complex rubber components, including large and intricate products. The defense, military, and medical industries frequently use this process to produce high-performance products such as O-rings, seals, and gaskets.

Why Partner With RD Rubber for Your Custom-Molded Rubber Components?

Finding the right company to manufacture your compression molded rubber parts is key to ensuring high-quality end products. At RD Rubber Technology, we understand our customers’ need for a responsive provider with sufficient capabilities and systems that meet high-quality standards for every application.

Our team of compression molding rubber experts can provide one-on-one service based on your individual needs. To provide consistent quality across our solutions, our products are made in the USA and we aim to serve as your local manufacturer.

The RD Rubber Difference

As a local manufacturer, RD Rubber delivers engineered-quality solutions when you need them. Our domestic supply chain mitigates logistics risks, preventing potential delays and other issues from negatively impacting delivery.

We exceed our customers’ expectations by providing superior product development engineering. Every part we manufacture is critical to our customers’ success. We prioritize communication and work to understand each customer’s unique requirements, which allows us to engineer quality finished parts.

What sets our technology apart is our unrivaled attention to detail, along with our combination of expertise and resources. Through our consistently dependable services, we have helped reduce production lead times and provide customers with engineered quality parts that are manufactured in the USA.

Compliance With the Latest Standards for Quality Assurance

To help make sure each product meets the same standard of quality, we use our ISO 9001:2015 and AS 9100:2016 Certified Quality Management System to keep track of the entire process, from quotation to shipping.

Our commitment to quality is evident through our numerous certifications and registrations, which include:

- DOD Joint Program Certification

- ISO 9001:2015

- AS 9100:2016

- ITAR Registered

- NIST 800-171 compliant

- Conform to Military Specifications

- MIL-I-45208A

- ANSI Z540-1ISA 10012-1 and ISO 3601-3

- GMP Standards

Contact us if you would like to learn more about our capabilities. Or, if you need to get started on a custom rubber compression molding project with us, request a quote.