RD Rubber Technology Corporation customers rely on our high consistency rubber injection molding materials and capabilities for their critical to function applications. We maintain the following certifications and registrations:

- ISO 9001:2015

- AS 9100:2016

- Department of Defense (DOD) Joint Certification Program (JCP) certified

- ITAR registered

In addition, we conform to and are compliant with the following:

- NIST 800-171 compliance

- Conform to Military Specifications

- MIL-I-45208A

- ANSI Z540-1ISA 10012-1 and ISO 3601-3

- GMP standards

Learn more about rubber injection molding, the materials we use, and applications that benefit from this efficient, cost-effective manufacturing method.

Common Materials Used in Rubber Injection Molding

Rubber injection molding is compatible with many thermoset elastomers and a variety of shapes and geometries. Materials are selected for specific characteristics, such as resistance to chemicals like oils or solvents, resistance to temperature damage, resistance to weathering and abrasion, and resistance to harsh environments. Mechanical characteristics like strength and elasticity, and MIL-SPEC or industrial standard requirements are also important.

At RD Rubber Technology, we often work with the following materials:

- Butyl: Durable and resistant to abrasion, wear, and tearing, also highly resistant to weather, ozone, polar solvents, alcohols, ketones, some esters, and some brake fluids.

- Ethylene Propylene Diene Monomer (EPDM): Excellent heat, UV, and weather resistance.

- Fluorocarbon (FKM/Viton): Extremely resistant to chemicals, including oils and fuels, and exhibits high-temperature stability.

- Fluorosilicone: High temperature stability and resistance to fuels and oils.

- Neoprene: Resistance to chemicals, ozone, and weathering.

- Nitrile Rubber (NBR): Resistant to chemicals, including fuel and oil.

- Silicone Rubber: Biocompatible, durable, and with excellent heat resistance.

- Urethane: Good elasticity, high degree of abrasion resistance.

Benefits of Manufacturing With Rubber Injection Molding

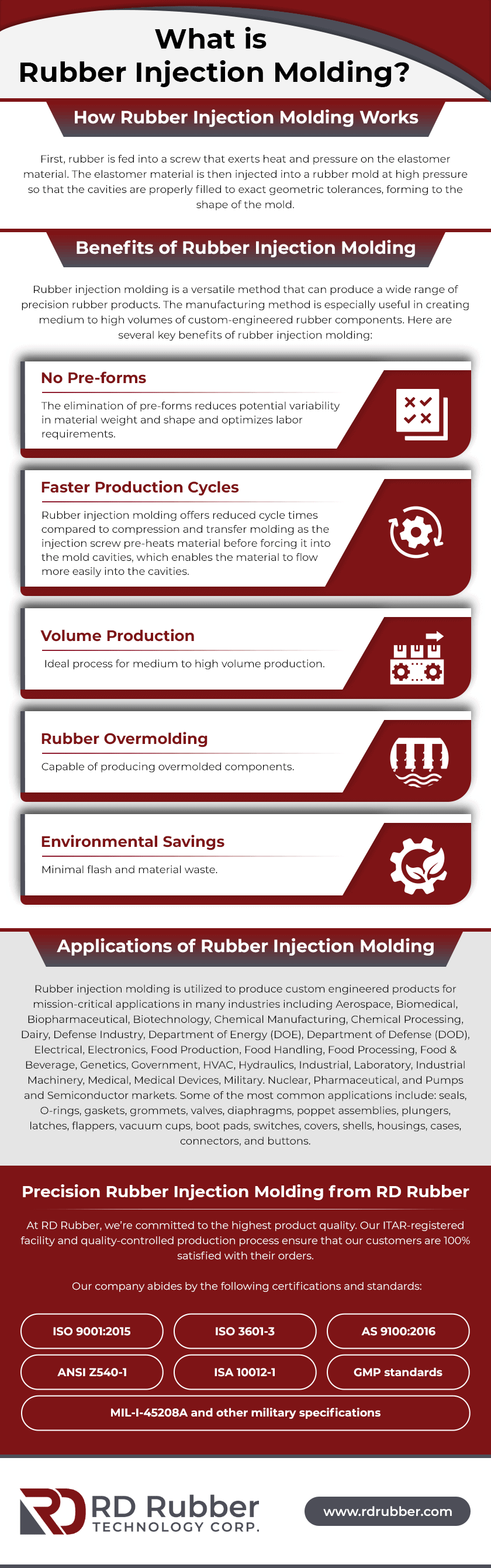

Rubber injection molding offers several advantages over other high-volume manufacturing methods. It’s incredibly versatile because when well-designed, cavity molds can be customized to a wide range of shapes and sizes for specialty applications.

Rubber injection molding does not require any preforms, which reduces labor, complications, and variability in product shape or weight. The process produces significantly less flash and has shorter production times than rubber compression molding.

Rubber Injection Molding Applications

RD Rubber Technology offers comprehensive custom rubber molding solutions for critical-to-function applications in demanding industries such as:

- Aerospace

- Biomedical

- Biopharmaceutical

- Biotechnology

- Chemical Manufacturing

- Chemical Processing

- Dairy Processing

- Defense Industry

- Electrical/Electronics

- Food Production

- Food Processing

- Government

- HVAC

- Hydraulics

- Industrial

- Laboratory

- Industrial Machinery

- Marine

- Medical Devices

- Military

- Nuclear

- Pharmaceutical

- Pumps

- Semiconductors

- Space

Rubber injection molding is well-suited for producing engineered rubber products such as seals, O-rings, gaskets, grommets, valves, diaphragms, poppet assemblies, plungers, latches, flappers, vacuum cups, boot pads, switches, covers, shells, housings, cases, connectors, and buttons.

Precision Rubber Injection Molding From RD Rubber

Rubber injection molding is a versatile process for rapidly producing medium- to-high-volumes of custom components. It is compatible with a variety of synthetic rubbers, and molds are customized to meet your application requirements, including intricate or complex designs.

At RD Rubber Technology Corporation, we specialize in quality-engineered custom rubber products for government contractors, the military, aerospace, medical device companies, and other regulated industries. We manufacture and deliver all of our products in the USA from our California-based facility. Contact us today to discuss your next project, or request a quote for pricing details.