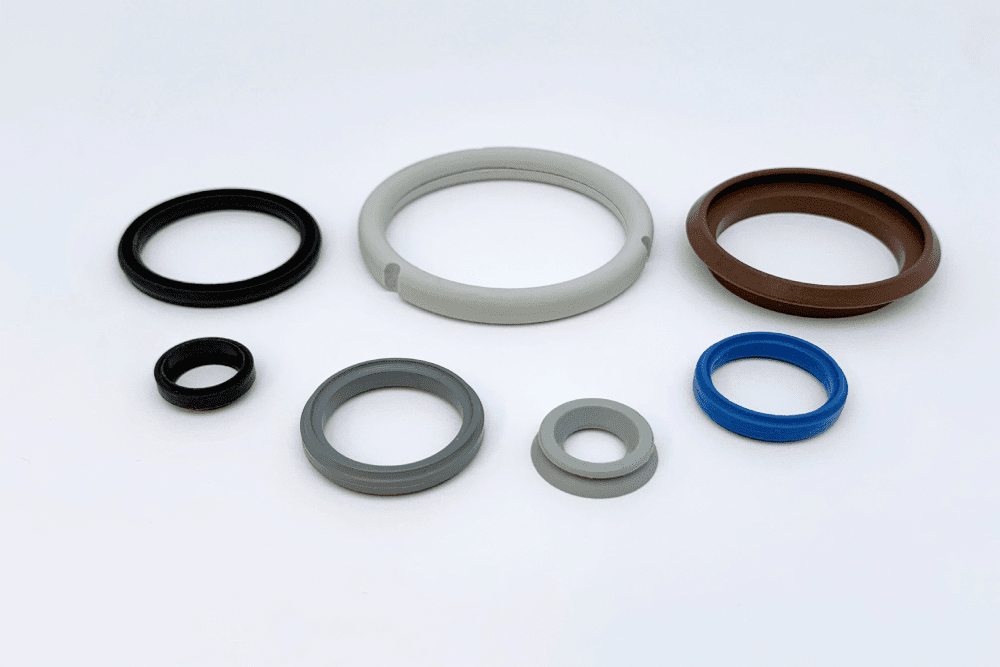

Molded rubber components are incorporated into a wide range of products, applications, and industries from aerospace and defense to medical device equipment. Critical to function applications require custom molds and tooling to meet customer-specific engineering specifications. It’s an efficient way to manufacture engineered rubber products in specific shapes, sizes, and materials. From gaskets and seals to grommets and poppets, molded rubber products are widely used for making secure connections between components, protecting component edges and openings, and keeping fluids contained.

RD Rubber Technology Corporation is an experienced manufacturer of critical to function molded rubber parts for aviation, space, military & defense, medical, food & dairy processing applications, and more. We are ISO 9001:2015 and AS9100:2016 certified, NIST 800-171 compliant, and Department of Defense and ITAR registered.

Learn more about our range of rubber molding capabilities, how these components are used, and some commonly used materials for molded parts.

Custom Rubber Molding Processes

There are several methods of producing custom-molded rubber products. The size, shape, relative complexity, and production volume of the part are some of the important considerations RD Rubber will make when determining which method is best.

At RD Rubber, we offer a variety of custom rubber molding processes, including:

Rubber Compression Molding

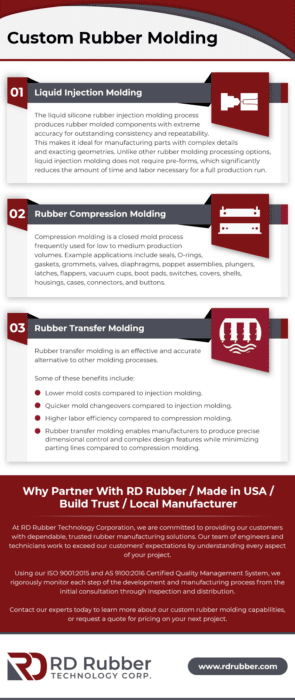

Rubber compression molding is a closed mold process frequently used for low to medium production volumes. Example applications include seals, O-rings, gaskets, grommets, valves, diaphragms, poppet assemblies, plungers, latches, flappers, vacuum cups, boot pads, switches, covers, shells, housings, cases, connectors, and buttons. In rubber compression molding, an uncured rubber profile or preform is carefully positioned into a heated mold and then into the compression molding press which subjects the mold to high clamping pressure to fill the mold cavity with the preform material. The rubber conforms to the shape of the mold and is cured to produce a molded component. Compared to rubber injection molding, rubber compression molding offers quick mold changeovers with longer material cure and production cycle times combined with lower mold tooling costs.

Rubber Transfer Molding

Rubber transfer molding begins by measuring the required uncured material and positioning it into the “pot” section of the transfer mold. The transfer mold is then closed and placed into the molding press. The plunger compresses the material as heat is applied, and the ensuing pressure transfers the uncured rubber through the runners into the mold cavities to cure the material to the desired shape. The next step involves trimming or deflashing to remove unwanted overflow material or flash. Rubber transfer molding provides precise control of dimensional tolerances. Although rubber pre-formed materials are required, a single rubber pre-form can fill multiple mold cavities.

Rubber transfer molding is more labor efficient compared to rubber compression molding but produces more material waste.

Rubber Injection Molding

Rubber injection molding is a manufacturing process that involves injecting uncured high consistency rubber (HCR) into a mold to create precise, highly engineered products. First, rubber is fed into a screw that exerts heat and pressure on the elastomer material. The elastomer material is then injected into a mold at high pressure so that the cavities are properly filled to exact geometric tolerances, conforming the rubber material to the shape of the mold. Rubber injection molding is a versatile method that can produce a wide range of critical to function rubber products. The manufacturing method is especially useful in creating medium to high volumes of custom-engineered rubber components. Here are several key benefits of rubber injection molding:

The elimination of pre-forms reduces potential variability in material weight and shape and optimizes labor requirements. Rubber injection molding offers reduced cycle times compared to rubber compression and transfer molding as the injection screw pre-heats material before forcing it into the mold cavities, which enables the material to flow more easily into the cavities. Rubber injection molding is an ideal process for medium to high volume production and is capable of producing overmolded components with minimal flash and material waste.

Rubber injection molding is utilized to produce custom engineered products for critical to function applications in demanding industries including Aerospace, Defense (DOD), Space, Biopharmaceutical, Medical, Chemical Manufacturing, Chemical Processing, Food and Dairy Processing and Electronics.

Applications include seals, O-rings, gaskets, grommets, valves, diaphragms, poppet assemblies, plungers, latches, flappers, vacuum cups, boot pads, switches, covers, shells, housings, cases, connectors, and buttons.

Liquid Silicone Rubber (LSR) Molding

Liquid silicone rubber is pumped from different types of containers, varying from sealed tubes to 55-gallon drums, through specialized hoses and tubing to the molding equipment. The two material components (A and B) are pumped through a static mixer by a metering pump. Once the two components are mixed, the curing process begins immediately. A chiller supplying cold water to jacketed fittings is typically used to slow the curing process prior to the materials entering the heated mold. Color pigments can also be added with a color injector together with the material pump before the material enters the static mixer section. In the static mixer, the material components are mixed and transferred to the temperature-controlled metering section of the injection molding machine. This contrasts with high consistency rubber (solid) rubber materials that are purchased pre-mixed and un-vulcanized. The mixed compound is then pushed into a heated cavity to vulcanize the material.

The liquid silicone rubber injection molding process produces silicone rubber molded components with extreme accuracy for outstanding consistency and repeatability. This makes it ideal for manufacturing parts with complex details and exacting geometries. Unlike other rubber molding processing options, liquid silicone rubber molding does not require pre-forms, which significantly reduces the amount of time and labor necessary for a full production run.

The comparatively low viscosity of liquid silicone rubber allows the cavity to fill quickly for quicker cycle times, thereby shortening production and reducing overhead. In addition, this method uses the precise amount of material required for each part to minimize waste.

Materials Used in Customer Rubber Molding

Many materials are compatible with custom rubber molding processes. As always, the requirements of the application will determine the best material options, and the experts at RD Rubber can help with this determination as well. We regularly work with materials including, but not limited to:

- Buna-N (Nitrile, NBR)

- Buna-S (SBR)

- Butyl

- Chlorobutyl

- EPDM

- Fluorocarbon

- Fluorosilicone

- Liquid Silicone

- Polypropylene (Neoprene)

- Silicone

- Viton® (FKM)

Applications of Custom Rubber Molding

RD Rubber serves the following industries with custom rubber molded poppets, valves, latches, grommets, gaskets, O-rings, seals, and more:

Aviation / Defense / Space

Custom molded rubber products in these industries are often used in harsh operating conditions, needing to withstand very high and low temperatures, and high performance expectations. Molded rubber parts are used in these systems and equipment:

- Avionics

- Engines

- Fuel systems

- Hydraulic systems

- Vibration dampening

- Thrusters

Food and Dairy Processing

The food and dairy processing industries rely on custom-molded rubber components for temperature-resistant rubber seals and gaskets on cooking and refrigeration equipment, conveyor system parts, and sealing rings and gaskets on storage containers. USDA food-safe silicone rubber is one of the common material choices for these applications, along with other high-quality, food-grade materials that keep contaminants out of process lines.

Medical / Pharmaceutical

RD Rubber manufactures dependable, high-quality parts from silicone rubber and liquid silicone for medical and pharmaceutical uses. These materials offer exceptional biocompatibility, chemical inertness, and the ability to withstand sterilization.

Examples include:

- Components for biopsy procedures

- Intravenous (IV) equipment

- Medical devices

- Pharmaceutical products and manufacturing

- Respiratory therapy equipment seals

- Surgical instruments

- Ventilator equipment

Semiconductors / Electronics / Instrumentation

Semiconductor processing environments generate high heat as well as corrosive and aggressive liquid chemicals. Electronics and instrumentation also require secure seals that block dust and contaminants. Custom molded rubber parts used in these industries, such as O-rings, gaskets, seals, and grommets, must be rated for high performance.