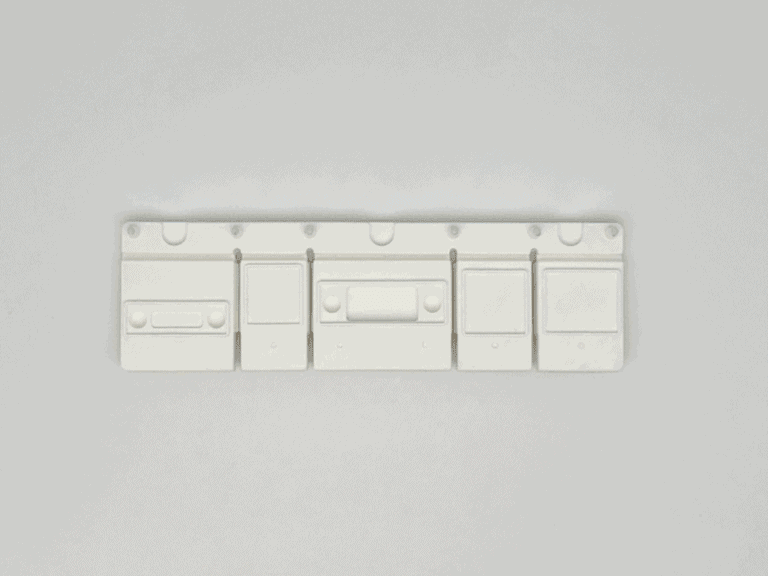

Santa Fe Springs, CA – RD Rubber Technology Corporation is pleased to announce it has been awarded multiple medical prototyping purchase orders featuring various custom rubber molding capabilities including compression, transfer injection and liquid silicone rubber molding processes. “Our customers rely on us to provide quality engineered custom prototypes for their product development requirements” stated Greg Sallee, RD Rubber’s President. “Our engineers are able to adapt our manufacturing processes to support protype and low volume orders to meet the product development needs of our customers. The medical, healthcare and pharmaceutical industries frequently use our prototyping capabilities due to our customer service and engineer-to-engineer communication throughout the development process.”

RD Rubber Technology is a leading supplier of custom molded rubber products for Aerospace, Defense, Medical, and high technology industries that require precision-molded elastomeric components. RD Rubber operates a state-of-the-art molding facility that includes ISO 14644 Class 8 cleanroom space and an extensive inspection and testing department. RD Rubber’s development team assists customers with process engineering and identifies the most appropriate compound for a specific application. With its chemical and mechanical rubber to metal & silicone to plastic bonding capabilities, RD Rubber can accommodate specialized engineering requirements and reduce the number of components in an assembly. RD Rubber also offers value-added machining, grinding, and finishing while molding any thermoset elastomer including organic rubber, synthetic rubber, fluorocarbon rubbers, fluorosilicone, and silicone types in the 10 to 90 durometer range. The RD Rubber team can make a recommendation and create custom formulations to meet application-specific performance criteria like compression set, permeation, and environmental resistances and offer a custom color match.