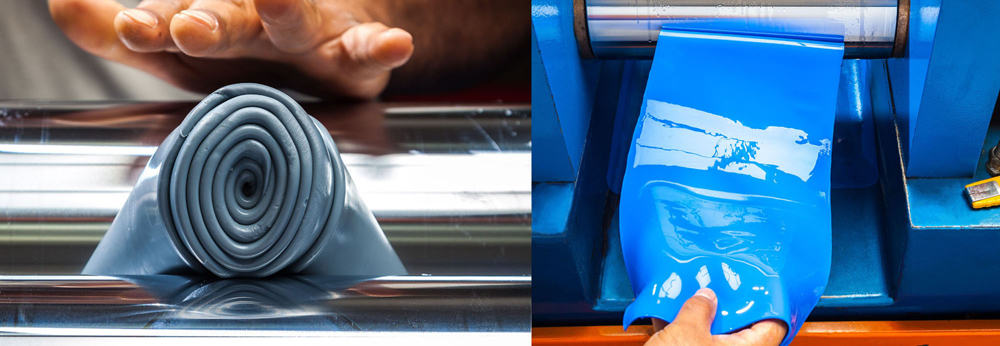

RD Rubber Technology molds all thermal set elastomers in LIM/LSR molding, Injection, Transfer and Compression Molding processes.

We offer molding capabilities for any thermoset elastomer including organic rubber, synthetic rubber, fluoroelastomer, fluorosilicone, SBR, butyl, chlorobutyl, EPDM, neoprene, nitrile, FKM, Viton® and silicone types in the 10 to 90 durometer range. We also offer custom material formulations to meet application-specific requirements including the customization of attributes like compression set, permeation, and environmental resistances and color matching. All elastomeric, rubber and silicone products are custom molded in a lean, ISO 9001/AS9100 certified manufacturing environment.

We create material formulations to meet your product specifications. By sharing with us your part environment requirements we will work with you to develop and recommend a material suitable for your specific application.

In the silicone family of materials, LIM/LSR standard products are available for a wide variety of applications or we will assist you in customization of materials such as:

- Silicone (LIM and HCR)

- Fluorosilicone

- Organic Rubber – EPDM, Butyl, Neoprene, Urethane, Polyisoprene, Natural Rubber, SBR et al.

- Fluorocarbon Rubber – Viton, Fluorel, FKM

Our Material Selection Guide will be helpful for your basic compatibility reference purposes, but keep in mind that these will need to be developed and customized.