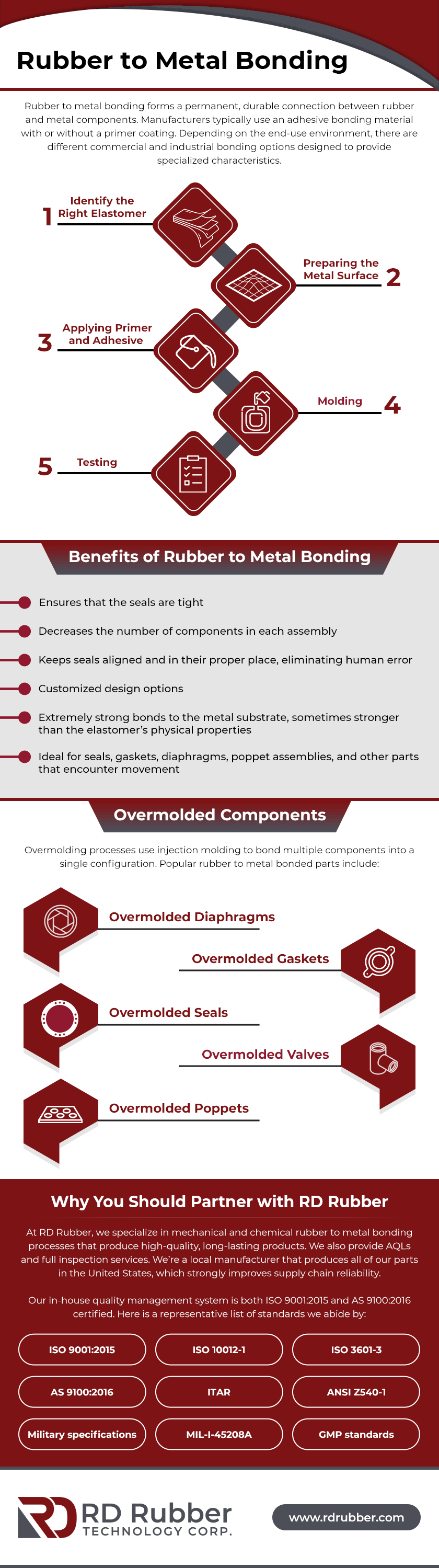

Rubber to Metal Bonding

Rubber to metal bonding forms a permanent, durable connection between rubber and metal components. Manufacturers typically use an adhesive bonding material with or without a primer coating. Depending on the end-use environment, there are different commercial and industrial bonding options designed to provide specialized characteristics. Learn more about the rubber to metal bonding process, its benefits, and common applications.

The 5 Steps of Rubber to Metal Bonding

Although various rubber to metal bonding processes differ, they all follow the same basic sequence of steps, as outlined below.

1. Identify the Right Elastomer

Natural and synthetic rubbers can both be bonded to metal substrates, but they require different preparation methods and are paired with different fillers to give the material new characteristics. At this stage, the rubber does not exhibit its desired properties until it is cured in the molding process.

2. Preparing the Metal Surface

After deciding on the proper elastomer material, manufacturers prepare the surface of the metal substrate. First, the surface needs to be thoroughly cleaned with a degreasing solvent and stored away from moisture. If the parts need to be handled manually, technicians should wear gloves or use a cloth so the parts are maintained in pristine condition.

3. Applying Primer and Adhesive

Once the metal is cleaned, manufacturers apply either a one-step adhesive coating or a two-step primer and adhesive coating. RD Rubber’s chemical bonding solutions comply with ASTM D429 standards.

Chemical adhesives are applied through dipping, rolling, spraying, or brushing the substrate. The ideal thickness for the primer should be about 0.2 to 0.4 mil and 0.5 to 1.0 mil for the adhesive. The coating then needs to dry and set in a low-humidity environment free of contamination.

RD Rubber also performs mechanical bonding, in which rubber materials flow through channels or holes in the metal substrates. This creates a strong rubber bonding to metal on its own or assists the chemical bonds to stay intact over time.

4. Molding

After the adhesive application, the molding stage should take place as soon as possible.

A common molding technique is rubber compression molding, which is a closed mold process that produces low to medium volumes of rubber to metal bonded components. Compression molding involves positioning an uncured rubber preform or profile into a heated mold, which applies high clamping pressure to fill the cavities with the rubber material. The rubber takes the shape of the mold and is cured into a finished molded component. Once the part finishes curing, technicians cut off excess material and set aside the bonded parts.

5. Testing

After molding, the parts are tested to ensure the bond, tensile strength, and other properties meet customer specifications. Manufacturers also test the components according to the standards established in ASTM D429. Common performance modes to test include 1) the strength of the rubber and adhesive bond, 2) the strength between the primer and adhesive layer, and 3) the strength between the adhesive and the metal.

Benefits of Rubber to Metal Bonding

Today’s consumer, commercial, and industrial goods commonly feature rubber to metal bonded parts. Some of the key benefits of rubber to metal bonding include:

- Ensures that the seals are tight

- Decreases the number of components in each assembly

- Keeps seals aligned and in their proper place, eliminating human error

- Customized design options

- Extremely strong bonds to the metal substrate, sometimes stronger than the elastomer’s physical properties

- Ideal for rollers, seals, and other parts that encounter movement and force

Common Applications of Rubber to Metal Bonding

Rubber to metal bonding is commonly used for these applications.

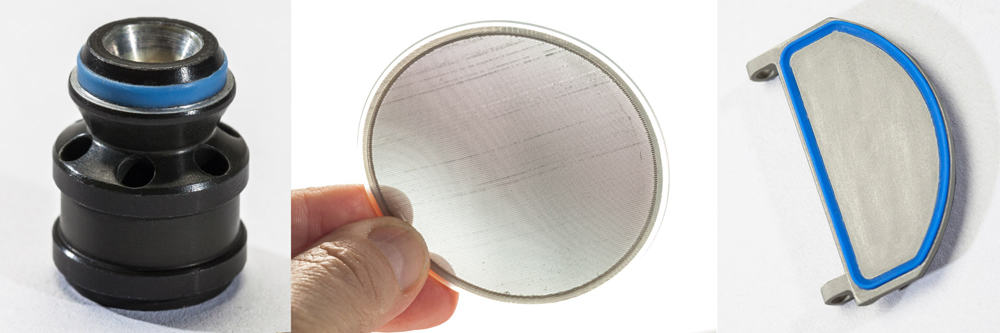

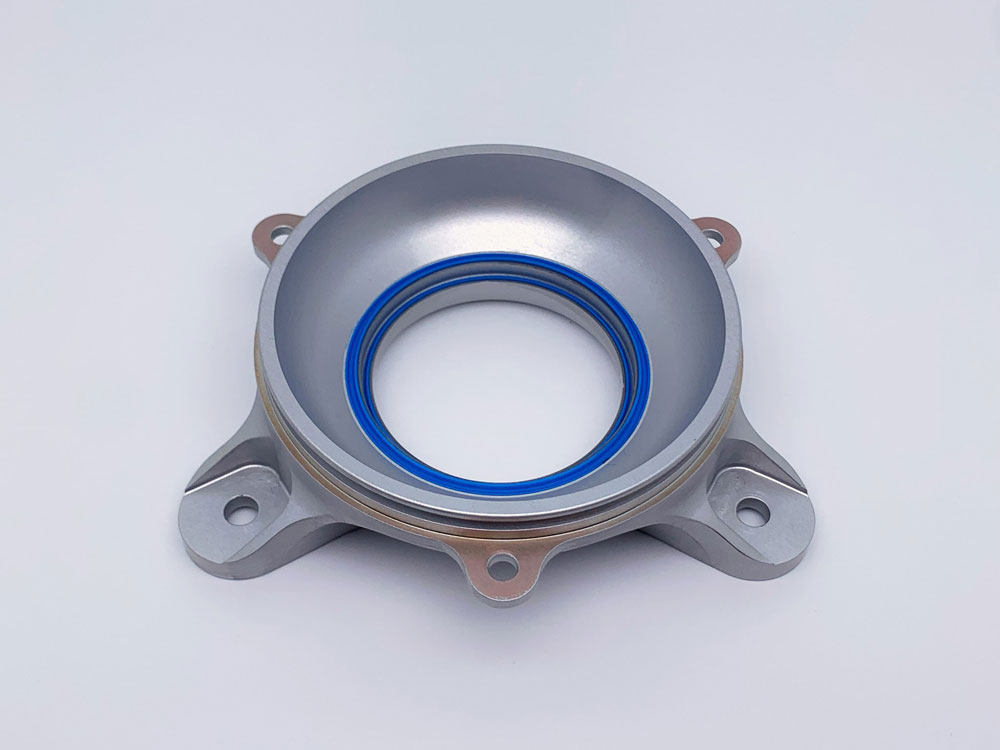

Overmolded Components

Overmolding processes use injection molding to bond multiple components into a single configuration. Popular rubber to metal bonded parts include:

- Overmolded diaphragms

- Overmolded gaskets

- Overmolded seals

- Overmolded valves

- Overmolded poppets

Industrial Components

Rubber to metal bonding techniques are effective in forming a wide array of small components for complex assemblies. Some of these components include:

- Boot pads

- Buttons

- Cases

- Connectors

- Covers

- Flappers

- Housings

- Instrument handles

- Latches

- Nozzles

- Plungers

- Poppets

- Shells

- Switches

- Vacuum cups

Why You Should Partner with RD Rubber

At RD Rubber, we specialize in mechanical and chemical rubber to metal bonding processes that produce high-quality, long-lasting products. We also provide AQLs and full inspection services. We’re a local manufacturer that produces all of our parts in the United States, which strongly improves supply chain reliability.

As an established rubber product supplier, we are dedicated to solving our customers’ problems and building long-term relationships with them through expert customer service and high-quality product deliveries. Our in-house quality management system is both ISO 9001:2015 and AS 9100:2016 certified. Here is a full list of standards we abide by:

- ISO 9001:2015

- ISO 10012-1

- ISO 3601-3

- AS 9100:2016

- ITAR

- ANSI Z540-1

- Military specifications

- MIL-I-45208A

- GMP standards

We understand that quality products are vital to your success, so we take the time to engineer and manufacture unique solutions or alternatives that can cut down on your production time and costs. Contact us today to learn more about our products, capabilities, and certifications.